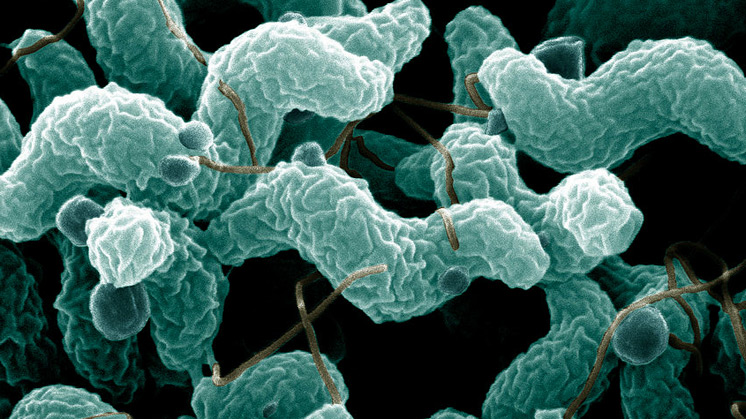

Chlorine Dioxide in Carcase Wash

To obtain efficacy data and practical operating details including costs on application of chlorine dioxide water as a decontaminant in poultry processing

Project Outline

Chlorine Dioxide ClO2 up to a maximum level of 0.5ppm was added to the water used for the washing of carcases during processing, and comparing the effect against a previous baseline study using potable water.

A minimum of 1 flock per week was sampled.

The neck skins of the carcases were tested for both Campylobacter and for the total viable count (TCVs).

Results

The addition of ClO2 in wash after evisceration and to the inside /outside wash and ISOS wash made no significant difference to microbiological status of the neck flaps of birds results compared with the baseline study.

ClO2 was also introduced in the pre-chill water for approx 6 weeks. The results of these flocks appear to show a small improvement compared to baseline but this was based on a small number of flocks and is not statistically significant.

An independent assessment of impact of chlorine dioxide treatment also found no evidence of an effect of the addition of chlorine dioxide to the water in the supply tank on Campylobacter counts.

Conclusion

The addition of Chlorine Dioxide at 0.5ppm to mains water for carcase washing does not reduce the enumeration of Campylobacter on the neck skins.